The mattress manufacturing giant is coming to the door: using “intelligent manufacturing” to impact the next 10 years

Latest News: “Manufacturing is the main body of the national economy, the foundation of a country, an instrument of rejuvenation, and the foundation of a strong country.” In the “Made in China 2025” strategy document, the opening paragraph points out that the manufacturing industry has an important role in China’s economy plays the role of “ballast stone”.

As early as 2010, China has become the world’s largest manufacturing country. By 2021, the added value of China’s manufacturing industry will account for 27.4% of GDP, with a total of 31.4 trillion yuan, ranking first in the world for 12 consecutive years, and its scale is equivalent to the sum of the United States, Japan and Germany.

In the process of rapid development of the manufacturing industry, some local brands have gradually emerged, first being accepted domestically, entering the stage of the rise of domestic products, and then the stage of international acceptance, becoming the symbol of global manufacturing.

The same is true for the mattress industry under the tide of domestic manufacturing. Under a new wave of change, domestic mattress brands are moving from China to the world, from “Made in China” to “Made in China”.

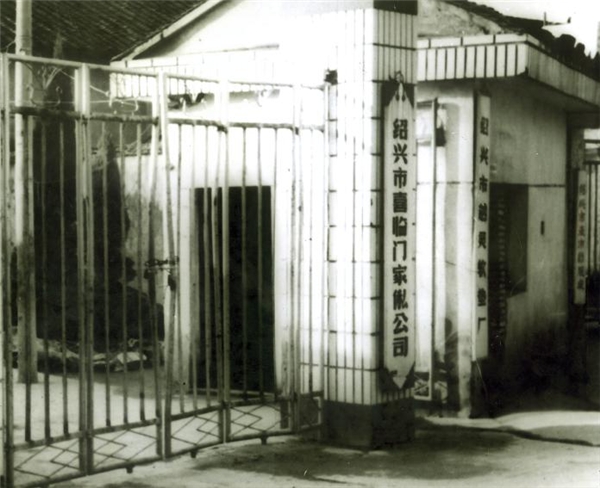

From remote small factory to manufacturing leader

At the 49th China International Furniture Fair held in Guangzhou recently, a product called Smart

M2’s smart mattress products once became the focus of attention at the exhibition. It applied four core technologies of ultra-quiet mattress adjustment system, intelligent matching algorithm, pressure sensing system and deep learning, which can realize personalized, intelligent soft Adjustable hardness to suit different body shapes.

It can also be seen from this product that the manufacturing capacity of domestic mattress companies has far surpassed the stage when they could only look up to foreign brands.

Behind this, a huge manufacturing system built by domestic enterprises competing and interconnecting with each other is gradually taking shape. Behind each of these industrial chains are the struggles of countless Chinese companies.

Take Xilinmen, the research and development company of the Smart M2 mattress, for example. From a small factory in Shaoxing, Zhejiang Province, to a leader in China’s mattress industry today, Xilinmen’s manufacturing capacity has gradually transformed in 38 years.

In 1993, Xilinmen developed its first patent, the hideable and liftable bed frame. Although the design is simple, it was already suitable for mass production at that time. In the second year, Xilinmen had its own production base and began to apply mechanized production equipment on a large scale, and the scale of mattresses took shape.

In 2000, the first fully automatic mattress production line in China was officially put into operation in Xilinmen. By 2002, Xilinmen, which had already made a name for itself in the domestic market, announced that it had become a strategic partner of IKEA.

In 2010, when the scale of China’s manufacturing industry surpassed the United States for the first time and became the world’s largest, the domestic manufacturing industry has entered a new stage of development – not only quantitative expansion, but also more and more qualitative improvement. Pay more attention to core technology, and enterprises pay more attention to development quality and efficiency.

Since then, Xilinmen has also entered a period of rapid development of patented technology. Since the listing of A-shares on July 17, 2012, Xilinmen has used the raised funds for the construction project of the northern furniture production line, the construction project of the soft bed and supporting product production line, and the upgrading and transformation project of the information system, so as to further strengthen its own manufacturing capacity. This also laid the foundation for its later becoming a manufacturing “behemoth”.

Manufacturing “behemoth” leads intelligent transformation

After 38 years of continuous cultivation, Xilinmen has established 9 major production bases around the world. The products are not only mattresses, but also products related to sleeping environments such as beds and sofas.

The “giant beast” is taking shape, but Xilinmen, who is in the wave of China’s manufacturing industry, is also facing the pressure of the times. Since 2012, the proportion of my country’s manufacturing industry has decreased year by year, and by 2021, it has dropped from the initial 32% to the current 27%.

Over the years, China’s manufacturing industry has been in the fast lane of rapid economic development. This part of the growth is mainly due to the continuous development of the “incremental” market. However, with the gradual stabilization of the economy today, how to further tap the “stock” market has become a problem. The problem of the next era.

In other words, although manufacturing is the engine of economic development, the gap between low-end manufacturing and high-end manufacturing is the key to whether Chinese companies can get out of the “low-middle-income trap”.

Refreshing “manufacturing” with “intelligent manufacturing” is Xilinmen’s answer. In 2018, Xilinmen, which is already in a leading position in the industry, officially determined its digital strategy and carried out the industry’s first 5G+ industrial Internet practice; in 2020, Xilinmen chose to use AI + big data as the core to enter the field of deep sleep to further strengthen its intelligent manufacturing capabilities. The intelligent transformation of the production line has basically realized the unmanned and intelligent production workshop of Xilinmen, which also means that the intelligent manufacturing of the domestic furniture industry has officially entered the 5G era.

Looking back now, Xilinmen, which has been on the market for 10 years, is accelerating its growth on the way to becoming an “intelligent behemoth”. From an industrial point of view, domestic mattress companies headed by Xilinmen have gradually transitioned from the stage of pure imitation to the second stage of having independent innovation capabilities and synchronizing with foreign companies. , how to lead has become a key issue for domestic enterprises to think about in the next step.