Covestro strengthens its low-carbon footprint TPU supply capacity in China

Latest news: Good news! The Shenzhen base has become another production base in the global family of Covestro that has been certified by the ISCC PLUS quality balance authority.

The Shenzhen base focuses on the production of thermoplastic polyurethane (TPU). Obtaining this certification means that it has the ability to provide customers with mass-balanced aromatic TPU containing part of the share of renewable raw materials in large quantities. By providing low-carbon footprint products, it helps the customer industry to move towards recycling. The economy moves further.

ISCC PLUS Mass Balance Certification

ISCC (International Sustainability and Carbon

Certification) is an internationally recognized certification system for sustainable development of biomass and bioenergy. The standard applies to all stages of the value chain and is recognized globally.

The TPU product portfolio based on mass balance contains a certain share of renewable raw materials and has a higher recyclability. It offers the same performance with a lower carbon footprint than its fossil-based counterparts. via ISCC

PLUS-certified TPUs can be applied directly to existing production processes without technical modifications or production interruptions.

Everything is new, more sustainable high-performance TPU solutions

As a new versatile and innovative material, thermoplastic polyurethane (TPU) is a melt-processable thermoplastic elastomer with a wide temperature range, a wide range of hardness, high durability and flexibility, excellent tear strength and cut resistance performance; and oil and solvent resistance, and strong hydrolytic stability and resistance to microorganisms. The Asia-Pacific region is currently the world’s largest TPU producing area, with nearly 70% of the output.

Covestro, as a solution specialist leading more sustainable and high-performance applications, is committed to making more sustainable TPU solutions a strong driving force for the realization of a circular economy. Today, our broad TPU product portfolio is used in many fields such as industry, agriculture, automotive, transportation, high-performance sports and leisure equipment, electronic appliances and smart wearable devices, infrastructure and basic processes.

In the middle of the last century, the company set up production bases in Europe and the United States, and began to sell TPU products in Europe and the United States.

In 2007, the company successfully integrated Shenzhen and Changhua bases and began to produce TPU locally in China. At present, the Changhua base in Taiwan is Covestro’s largest TPU production base in the Asia-Pacific region.

PLUS certified.

In 2019, through local integration, Covestro’s TPU business further opened up the Japanese market and increased its supply capacity and market share in the Asia-Pacific region.

With the Shenzhen base getting ISCC

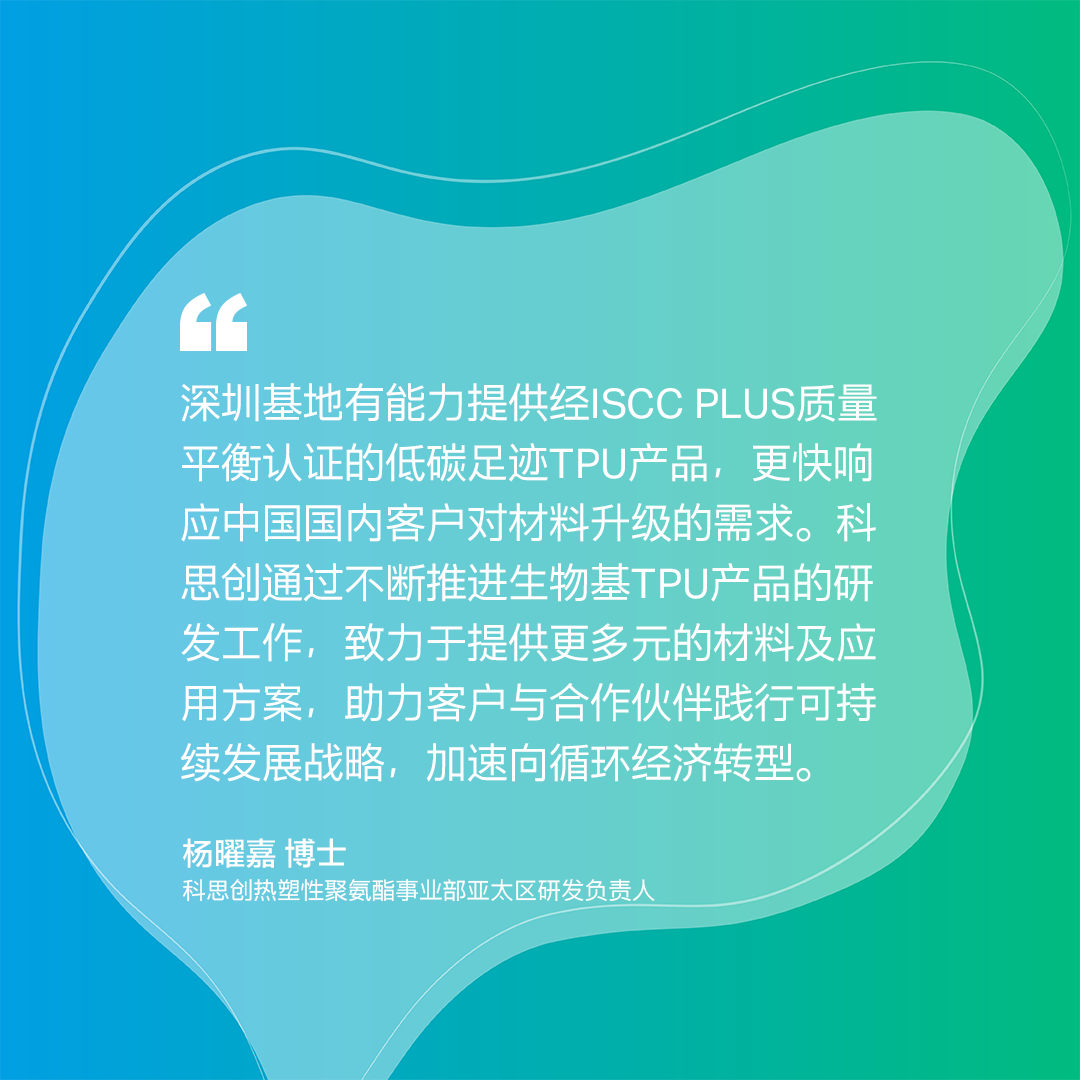

With the PLUS mass balance certification, Covestro further expands its ability to produce mass balance TPUs to meet the growing market demand for more sustainable products and solutions, with major application areas including technology, electronic digital and sports and leisure. Covestro has continuously upgraded the R&D strength and services of its Shenzhen and Changhua bases, and is committed to responding quickly to customer needs, providing customized services and finding ideal solutions. By continuously strengthening production and R&D capabilities, Covestro is committed to providing global customers with more sustainable and higher-performance TPU products.

Covestro is committed to actively promoting the use of alternative raw materials, and looks forward to helping more customers achieve their sustainable development goals and work hard to achieve climate goals and a circular economy!